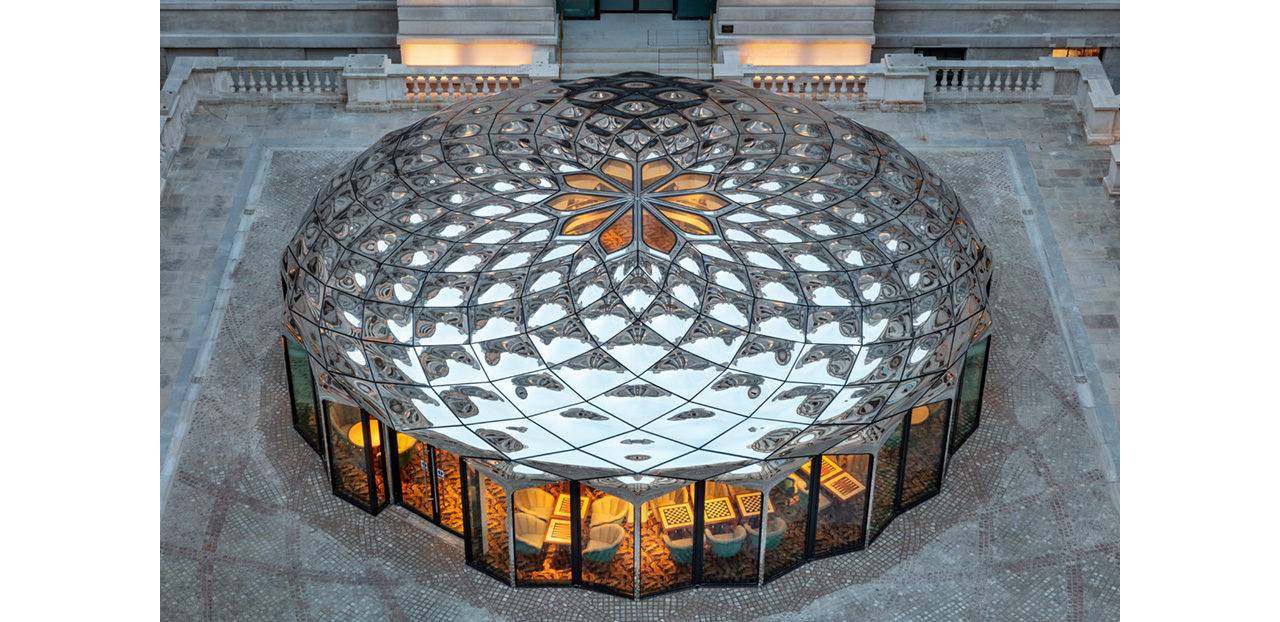

The OWO Courtyard Pavilion

In the Grand Courtyard of The OWO – the former Old War Office in Whitehall, London – a strikingly contemporary pavilion has been realised. Designed by DaeWha Kang Design, the structure blends architectural poetry with technical precision. The pavilion’s most eye-catching feature is its roof, clad in 3D-formed, mirror-polished stainless steel panels. Octatube translated the unique design into a buildable technical concept and was responsible for both the engineering and realisation.

Historical Context: Transformation of the Old War Office

The Old War Office is a Grade II* listed building with a rich political and military history. After years of vacancy, it has been redeveloped into The OWO: an exclusive destination featuring a 120-room Raffles hotel, 85 private residences, nine restaurants and three bars. The round pavilion in the courtyard is home to the French restaurant Café Lapérouse.

Geometric Refinement in the Roof Design

The pavilion’s roof is composed of 3D-formed, mirror-finished stainless steel panels arranged in a pattern reminiscent of sunflowers. This mathematically driven geometry – entirely devoid of straight lines – creates a light, dynamic presence within the historically monumental setting.

The undulating roof form demanded bespoke solutions and meticulous craftsmanship to the millimetre. Our engineers succeeded in preserving the original design intent while meeting the technical requirements for fabrication and installation.

3D Fabrication Model as a Communication Tool

Octatube provided full technical support, ensuring feasibility and mitigating risks. A detailed 3D fabrication model was developed based on the architect’s original geometry. From the outset, this model was used to:

- refine the challenging geometry,

- visualise the roof form to discuss complex detailing and interfaces,

- identify technical bottlenecks in fabrication and installation,

- and facilitate collaboration across disciplines.

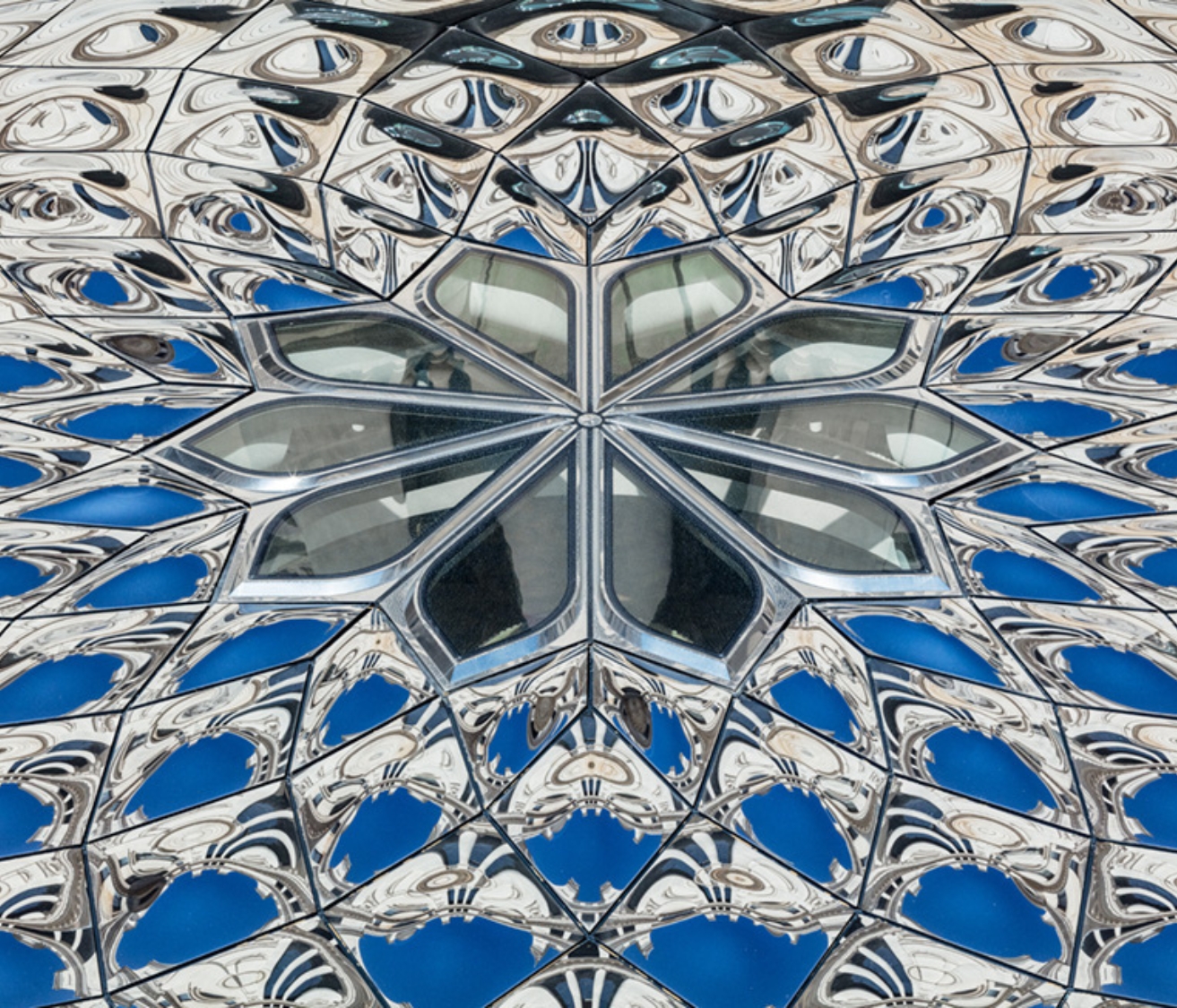

Mirror-Polished Panels: A Craft of Steel

Producing mirror-polished, 3D-shaped stainless steel panels requires specialist expertise. At only 2 mm thick, the panels are susceptible to deformation under heat, and even minor scratches or dents can compromise their visual integrity. Precision was essential.

To achieve the required quality, Octatube collaborated closely with specialist suppliers. Creating panels that faithfully reflected the 3D model involved:

- hydraulic 3D pressing,

- high-end laser cutting,

- meticulous manual polishing,

- and structural bonding combined with stud welding.

The result: 202 flawless panels, each one protected, inspected, and installed using bespoke detailing and specialised techniques to ensure a clean, secure fit.

Substructure and Installation: Invisible Precision

A 20 mm edge makes the thin panels appear thick and solid. Behind this visual effect lies a carefully engineered substructure. Z-shaped bent steel profiles on adjustable brackets provided a placement tolerance of just 2 mm. The mounting system uses structural bonding and stud welding. By avoiding visible steel connections, the roof’s aesthetic remains uncompromised.

Multi-Functional Mullions

Visually, the mirror-clad roof tapers down into a base composed of 42 vertical ‘stems’. These mullions were technically complex due to their shape, function, and slender profile. Each consists of two parts, with challenging geometry, pre-bent and welded in a custom jig to ensure precision and straightness.

Despite their multiple roles, the mullions were designed to appear as visually minimal as possible. They:

- act as tension members to counter uplift forces, rather than carrying compression loads,

- support the window frames,

- house the rainwater drainage system,

- and contribute to thermal insulation.

Transparency and Light: Façade and Rooflight

The pavilion structure comprises five steel columns with cantilevered arms. Atop this skeleton rest ten curved roof shells. At the centre of the roof is a flower-shaped rooflight, crafted to millimetre precision.

The unconventional forms required manual welding and polishing. The rooflight was hoisted into place in a single lift and aligned perfectly within the steel framework.

The façade consists of double-insulated glass panels featuring a graduated mirror coating at both the top and bottom. This transition delivers:

- visual calm,

- improved energy performance,

- and seamless integration with the reflective roof.

The window frames are made from a darker stainless steel to contrast with the mirror-polished mullions and roof.

Mock-Up and Precision in Execution

A full-scale visual mock-up (VMU) was created during the process to fine-tune details and improve buildability. The engineering and VMU development were executed in parallel within a four-month timeframe, allowing for refinement of every aspect of the design.

One of the greatest challenges during installation was alignment. High precision and the use of customised templates ensured smooth installation, perfect alignment, and the preservation of the design’s visual integrity.

Designed for Disassembly and Sustainability

Reusability was a key principle. The pavilion was constructed entirely with bolted connections, with no welding on site, making it fully demountable. It can be disassembled and reassembled at a different location without needing to reproduce any components. This significantly extends the material lifecycle and minimises waste.

The focus on reusability and material efficiency not only reinforces the pavilion’s sustainability credentials, but also sets a benchmark for future architectural projects that seek to balance innovation with environmental responsibility.

Collaboration Under Challenging Conditions

This technically and architecturally ambitious project was delivered in close collaboration with DaeWha Kang Design, Arup, Fielitz and others – much of it remotely during the COVID-19 pandemic.

Designing and constructing a 3D-formed stainless steel roof is an inherently complex and demanding task, requiring a high degree of skill, expertise and attention to detail. The result, however, is a true showpiece: light and mirrored reflections create a dynamic and ever-changing visual experience. The durability and longevity of the materials ensure that the roof will stand the test of time.

Instagram @theowo.london

Photographed by Kyungsub Shin