Central Plaza

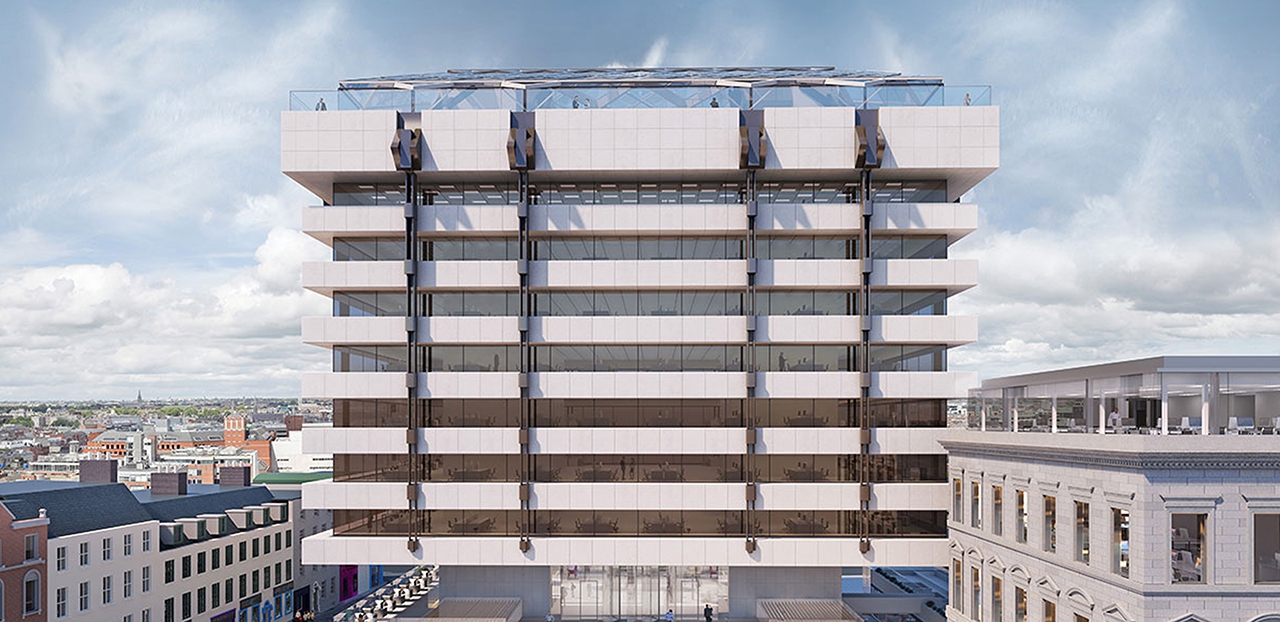

A striking two-storey roof structure made of glass and steel has been installed on the One Central Plaza in Dublin. The contemporary, geometric design by Henry J Lyons follows the visible supports of the building and features cantilevered triangles as a subtle reference to the original design. This structure crowns One Central Plaza and offers unparalleled 360-degree views of the city. As a Design & Build partner, Octatube did the engineering, production and assembly.

In the late 1960s, brutalist architect Sam Stephenson designed this concrete behemoth formerly known as the Central Bank building. The building can be seen from several places in the city. Hines (in collaboration with the Peterson Group) has transformed this building into a new destination that brings together offices, shops and restaurants.

The structure

We built the roof on the existing roof structure which is special and challenging in terms of design and structural engineering.The new steel rooftop structure measures 42.5 x 27.5 x 6 meters and weighs more than 200 tons. It consists of multiple steel RHS beams (400x200 mm and 200x100 mm) that are connected to each other by hidden bolted connections. The structure is a monolithic steel frame without expansion joints. And that gave our structural engineers a challenge: how to ensure that the roof structure can withstand temperature variations and the simultaneous deformation?

We applied fully glazed facade corners and disconnected the façade form the roof. When the temperature increases or decreases, and thermic expansion occurs, the roof can slide over the façade. It can expand and retract 30 and 15 mm, respectively. We carefully detailed the connection between the façade and the roof to allow this movement.

The glass

The steel roof construction is covered with 152 triangular, quadrangular or pentagonal glass units - celebrating lightness and transparency. The space offers optimal views. In order to achieve this we made the structure as sleek and clean as possible, facilitating maximum transparancy. It forms a counterpart to its brutalist carrier.

At the same time we have regulated the sun load. The glass is be screen-printed with a ceramic frit. It doesn’t feel like a greenhouse inside.

Challenges

The Central Plaza building is very unique; the structure comprises suspended floor slabs held up by perimeter Macalloy tension rods, that are supported back to the central core at roof level. A Brutalist characteristic: exposing the building’s structure.

.jpg) Photograph by Infomatique (Wikimedia Commons)

Photograph by Infomatique (Wikimedia Commons)

Live loading on the floors (i.e. people moving around) results in elongation of the tension rods. Thus, the outer perimeter of the 10th floor has relatively large deformations. To reduce the impact on the roof structure, additional compact bearing rubbers are applied at the anchors. When the floor moves downward due to live loading on the lower floors, the influence on the column is negated, which results in the reduction of loads on the roofs.

Mock-Up

We put much attention into detailing, in close collaboration with the client Hines, the architect Henry J. Lyons and the contractor Stewart Construction, ensuring what has been imagined can be delivered.

For Central Plaza we produced a mock-up, a scale model of a fragment of the roof in which different elements come together. It’s a method of testing that we like to incorporate in the design and engineering process. Most designs have not been realized before and the mock-up offers the possibility to check the design for efficiency. It gives an idea of the quality that can be expected in the new building. After the mock-up, small and smart alterations can be made before proceeding with the total production and assembly.

Assembly and logistics

We did the steel-production in our factory in Delft. The construction consists of more than 4000 parts such as bespoke columns, roof parts and (corner) beams.

The geometry of the building determined that the roof had to be build up from separate elements rather than larger weldments. This way, all elements got the best conservation and could be efficiently shipped to site. The steel structure and elements are connected to the main structure via different types of consoles and custom brackets. The elements were transported by truck from Delft to Dublin.

Standing on top of Central Plaza is a remarkable experience, taking in the abundance of light and vistas of Dublin. A revaluation of urban heritage and a breathe of new life in the heart of Dublin.