Park House

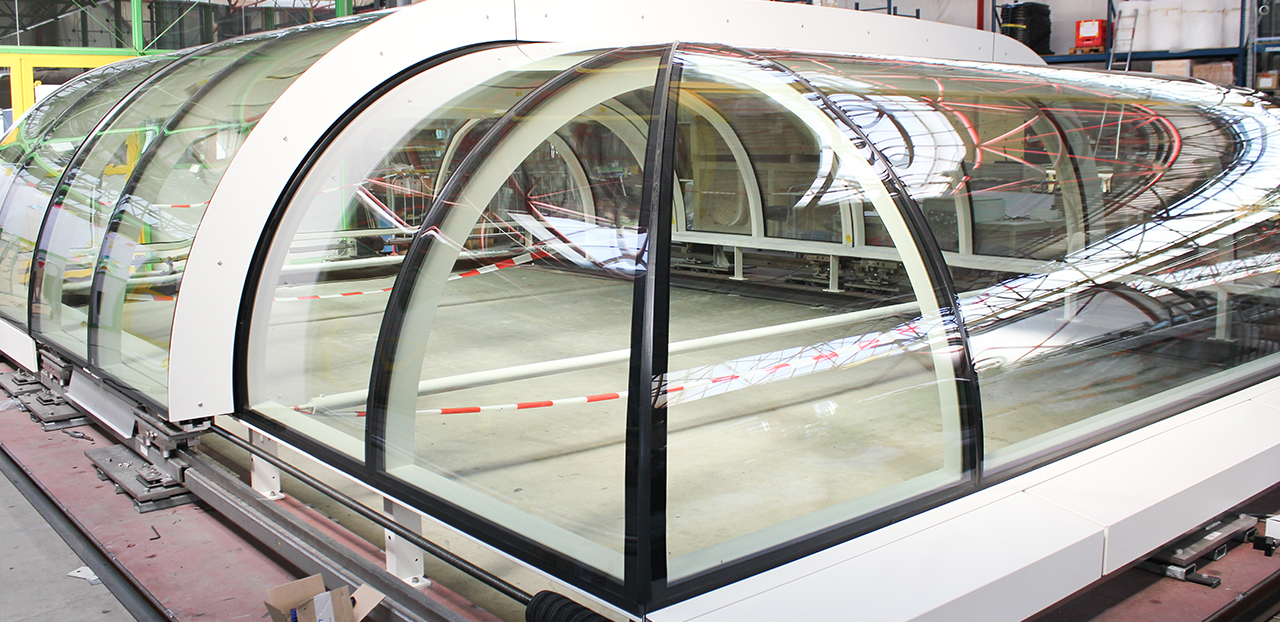

A relatively small retractable roof graces a private residence in the middle of London. But it is no ordinary retractable roof. On the contrary, the nonstandard shape of the roof, hot bent glass and the use of structural silicon sealant as only connection without any other mechanical fixing, makes it rather special.

Octatube was contracted for the design, engineering, production and installation of this retractable roof and of the steel glazed link structure in the same residence, that connects two building volumes. A challenging combination of a nonstandard shape, maximum slender steel profiles, hot bent glass and their tolerances and quality, unique silicon gluing, thermal behavior and the custom mechanical system for a smooth opening of the roof within 60 seconds.

Retractable without visible mechanism

The retractable roof is 10 meters long, 7 meters wide and 2 meters high. The mechanism for retraction is integrated in the limited available space. The high end stainless steel rails and ‘cars’ have been custom designed for this project. Together with the worm gears and the engine, it is fitted under the glazing on the outside of the retractable roof. Covered with a minimum casing of sheet metal making it completely out of sight. For the visual steel structure, which consists of solid profiles, a high quality water cutted steel is used and coated white.

Silicon sealant as fixing

Innovative about this roof is that the hot bent IGU glass units are connected to the steel structure with a 2-component structural silicon sealant, without any other mechanical fixings. For this purpose, a thin piece of stainless steel is applied to the steel structure, as sealant cannot adhere to the properly coated steel.

Glass corners

The glass corners were particularly challenging due to their rigid geometry and tolerances in the production process for hot bent glazing. To ensure a perfect fitting the corners are produced with a contra mould.

Pre-assembly and temporary provisions

To test if and how the roof sections would slide over each other when retracting, we assembled the roof in its entirety in our factory. After successful tests the four segments of the roof were transported to London. We made special temporary provisions and fittings to minimize tension in silicon sealant and glass during hoisting and transport to London. This minimized our time on site as well.

Glass link

The private building also contains a steel glazed link structure of 11 meters long, 5 meters wide and 2,5 meters high. This link connects two building volumes. It exists of solid steel profiles, coated warm white, of the same high quality used for the retractable roof, and flat rectangular triple glass panels.

In collaboration with:

Facade consultant: Eckersley O’Callaghan