Sammy Ofer Centre

From design to reality

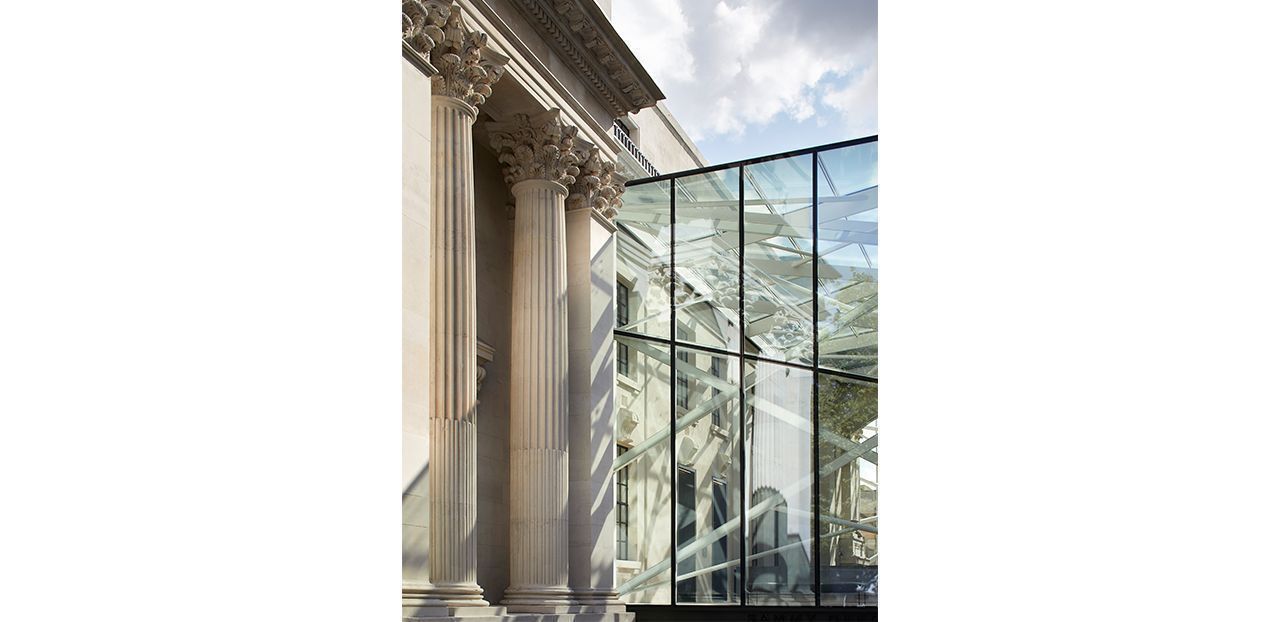

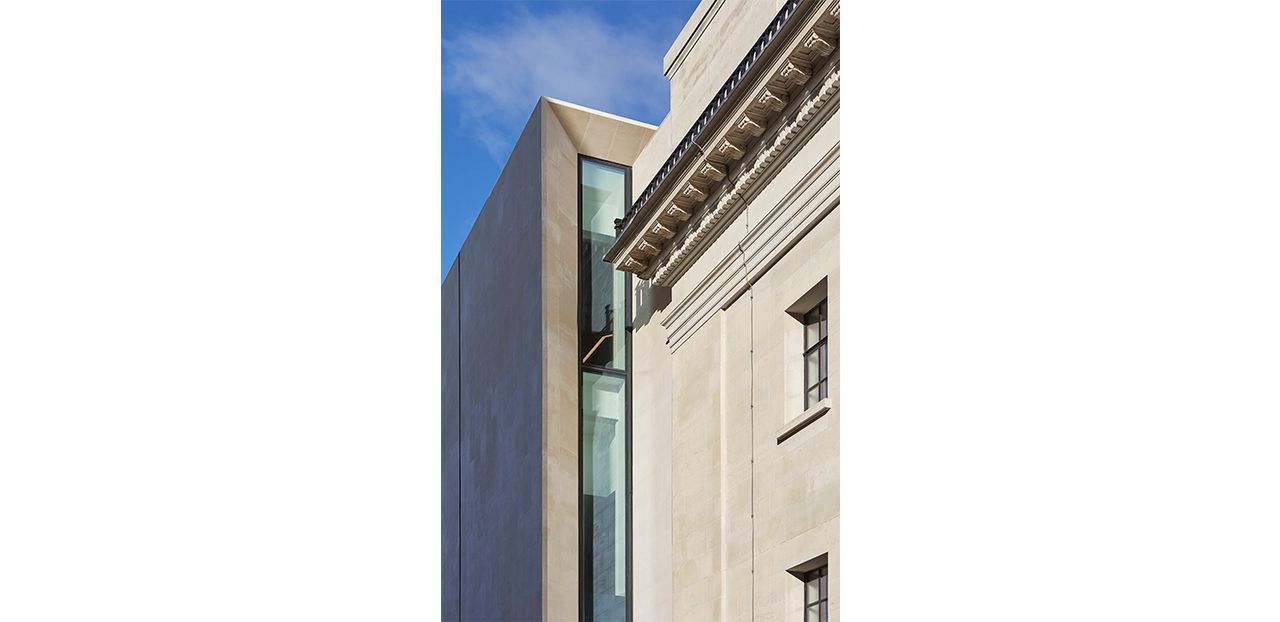

The architect firm Sheppard Robson was commissioned by London Business School to create a state-of-the-art teaching centre in the Grade II listed Old Marylebone Town Hall and Library Annexe. The design included the insertion of a glazed entrance foyer linking the two buildings, and a new lecture theatre block. While complementing the historic and architectural interest of the existing buildings, the link would also create a dynamic entrance to the London Business School (LBS). The plans were there but specialist knowledge was needed to make the design a reality. Octatube was approached by Wates construction following the succesfull collaboration on the Victoria & Albert museum.

Value engineering

The design was innovative and challenging at the same time. The Mikado like structure had to appear to hover under the glass whilst locked in place by the two neighbouring grade II listed buildings. Octatube started off by designing and engineering and came up with new ideas to produce and make this steel structure that would later be one of the key features of the Sammy Ofer Centre.

Several (engineering) solutions proved that Octatube could deliver the design within budget, on time and with an aesthetically high-quality finish.

Several mock-ups

Since most of our clients have a challenge in their project, we often realize pre-construction design mock-ups (before we start to build). Most of the time mock-ups are a fundamental part of the process. Mock-ups give us the opportunity to see if our design meets the vision and requirements of the client and the design team. The mock-ups we did for the LBS demonstrated that we could make satisfactory interface details with regards to primary steel, secondary steel, structural roof and façade elements, steel glazing rails, support elements, glazing, edge beams, external gutters, internal pressings, ‘Loop plates’ and all other elements proposed for the completed construction. The client could view the structure from different angles and see the actual finish of the works.

Design workshops

We are most proud of how we collaborated with the different parties. As a subcontractor we were part of the building team including the main contractor, the façade consultant, the architect and the client. We initiated design workshops with all parties every two weeks from the very beginning of the project. This created an open and trustworthy environment. The architect felt that we understood his design and the project swiftly moved forward with everybody’s dedication and enthusiasm to make this project a success.

Paolo Longo, architect at Sheppard Robson: “The collaboration with Octatube was extraordinary. This was altogether a different project. The design was very bespoke and required specific expertise. Octatube was able to deliver that. I enjoyed working together with their enthusiastic team of professionals. They gave good feedback and were pro-active in offering new ideas and organizing the design workshops.”

Challenge

The most challenging part of the structural design was the integration of the old with the new. The existing walls needed to be able to carry the weight of the new structure. This required good communication between all parties. Together we came up with ways to carry the new steel structure at the corner points of the existing stone walls. The structure had to be secured below the cornices on either side. The two existing cornices of the existing old buildings defined the maximal steepness for the new roof design, which turned out to be minimal, only 1.5 degrees, this required a very stiff structure in a limited available construction height. By working together and coming up with solutions these challenges were overcome and we managed to stay on schedule.

Creative solutions

Octatube came up with a novel idea to separate the by the architect so desired ‘seamless loop plates’ from the structural inner core in such a way that the divisions of the structural steelwork and the large loop plate elements ended up totally out of sight. By pre-manufacturing the steel frame in our own factory we ensured that the frame needed little welding on site. To fit the enormous steel frame into place in between the monumental buildings was a huge puzzle.

Lex Oosterom, project coordinator of Octatube: “The street alongside the building was too busy to close off for longer periods of time, thus we refrained from using a mobile crane. Instead, a tower crane was mounted on top of the roof. This crane was then used to install large prefabricated steel façade structures. This was a major challenge as the operating space for hoisting down the heavy frames was sometimes less than a centimeter wide. Fortunately, we managed to install all elements without damaging the existing stone cornices or other building parts. After that, the remainder of the construction works went by rapidly.”

Realization

The project is characterized by high-end material quality and a high level of craftsmanship, finishing and bespoke detailing. In addition to the Link structure, Octatube has replaced the 1960s section of the Council House with a new teaching block and the elegant central tower has a new interface with a lower situated self-supporting roof light. The overall design adds a modern learning environment to the historic premises, increasing the teaching spaces the School has available.

Dave Nott, director at Wates Construction: “The Octatube team, throughout the procurement, design, manufacture and install stages, played a significant role in ensuring the successful and timely completion of the Sammy Ofer Centre for the London Business School. The overall quality of what has been delivered is a testament to the efforts of our supply chain. Octatube is very much a key and valued member of our supply chain.”